New here? Register to get access to all the additional features.

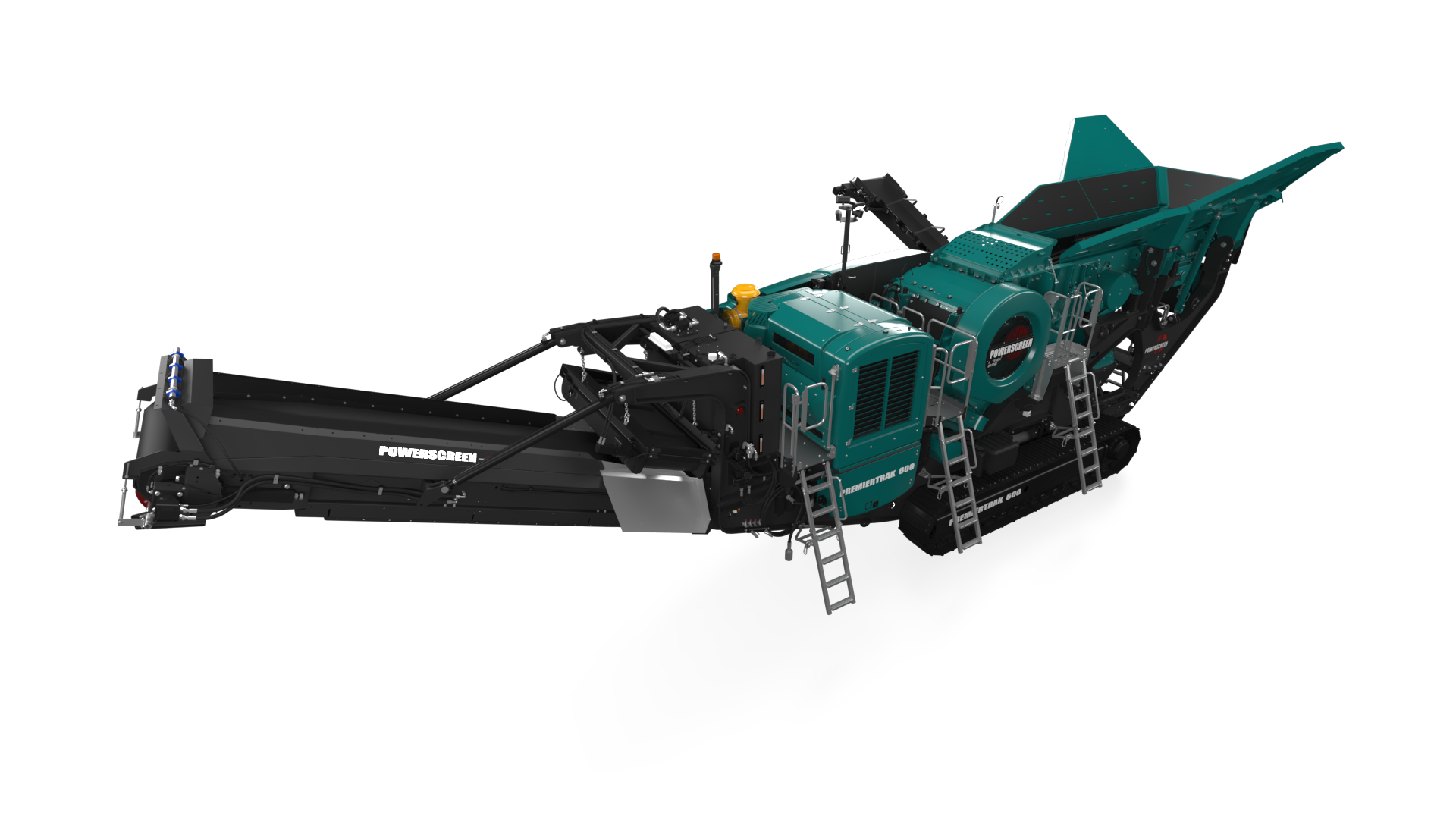

RegisterThe Powerscreen® Premiertrak 600 range high performance jaw crusher has been designed for large and medium scale operators in quarrying, demolition, recycling & mining applications. Built for the toughest of applications, the robust construction and modern design of the Premiertrak 600 ensures optimum performance, reliability and efficiency.

⚡This machine is available with Electric/Hybrid drive

⚡This machine is available with Electric/Hybrid drive

The Premiertrak 600E comes complete with an onboard diesel generator, with sufficient excess power available to run a second machine such as a screener. This

versatility along with the electrically driven crusher and conveyors makes the PT600E highly efficient, economical and environmentally friendly.

Hopper

Power Unit

Tracks

Product Conveyor

Feeder

Crusher

Measurements

Productivity

Downloads

Others